Please activate JavaScript in your browser to use all interface options.

- Labor safety

- Process safety

- Site safety

- Fire safety

- Road traffic safety

- Well control

- Geotechnical monitoring

- Aviation safety

To support its social responsibility, the Company voluntary invests significant financial and human resources into large-scale activities in labor and process safety over and above the legislative requirements.

The Company makes ongoing systemic effort to improve labor safety. It implements proactive and risk-based targeted programs according to latest international standards and best practices, such as fall prevention programs in subsidiaries.

The Company makes ongoing systemic effort to improve labor safety. It implements proactive and risk-based targeted programs according to latest international standards and best practices, such as fall prevention programs in subsidiaries.

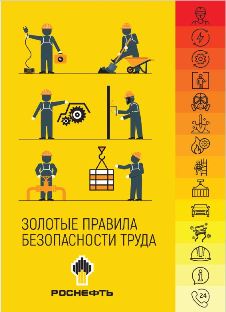

The Company makes sure that all employees, from blue-collars to top managers, adhere to the "Golden Safety Rules".

"GOLDEN SAFETY RULES" is a concise and visual guide describing safe ways of performing eleven most frequent hazardous operations. Types have been selected and safety rules given drawing on the experience of the leading oil and gas companies and accidents’ analysis.

The Company’s process safety management system (hereinafter referred to as PSMS) is integrated into the HSE management system, which is a part of the comprehensive corporate management system. A distinctive feature and an advantage of the PSMS is that this is an umbrella system covering all 4 classes of hazardous facilities. This goes way beyond legal requirements to apply it to only 1 and 2 class hazardous facilities. This approach ensures the consistency of safety management practices across the Company and higher levels of process safety in all subsidiaries.

Rosneft is consistently implementing new technologies to monitor the condition of its facilities. The Company's subsidiaries use drones for aerial monitoring of the ground infrastructure. A number of subsidiaries use modern mobile labs to monitor the condition of the oil pipelines and ground infrastructure. Mobile flaw detection system provides for better quality of information, ensures cost optimization and improves the overall level of process safety and environmental protection.

Business segments in Rosneft implement risk-based targeted programs to improve pipeline reliability and ensure integrity of its facilities. Special attention is paid to programs delivered in the Far North.

As per the Russian Federation fire safety requirements, the Company has established a fire safety system, one of the HSE IMS subsystems.

As per the Russian Federation fire safety requirements, the Company has established a fire safety system, one of the HSE IMS subsystems.

To make fire prevention and firefighting effective, the Company created a dedicated subsidiary RN-Fire Safety LLC, which has over 140 fire brigades equipped with up-to-date firefighting equipment and highly effective fire extinguishing agents. It made it easier to manage the corporate firefighting units, significantly improved their response time, set a single fire safety policy and optimized the implementation of the corporate programs.

The Company's high level of responsibility is evidenced by its participation in public regional and federal initiatives and projects. Rosneft is a member of the RF EMERCOM Working Group established to improve the fire protection system by strengthening the fire and rescue teams. Rosneft is also a member of a Technical fire safety standardization committee.

The Company operates more than 60K vehicles. Over 80% of which are equipped with in-vehicle monitoring systems and dashcams. In 2020, the Company developed a Road Traffic Safety Concept to streamline all preventive road safety processes. As part of the new system, subsidiaries have developed their own road accident prevention programs. They also organize road safety preventive campaigns and meetings inviting the representatives of local authorities, supervisory bodies, the State Traffic Police, and transport contractors.

The Company operates more than 60K vehicles. Over 80% of which are equipped with in-vehicle monitoring systems and dashcams. In 2020, the Company developed a Road Traffic Safety Concept to streamline all preventive road safety processes. As part of the new system, subsidiaries have developed their own road accident prevention programs. They also organize road safety preventive campaigns and meetings inviting the representatives of local authorities, supervisory bodies, the State Traffic Police, and transport contractors.

Well control processes in Rosneft are well described by the Well control Regulations. All Upstream Internal service subsidiaries train their staff and run emergency drills; some of them use computer simulators of well drilling and workover.

CCTV and video recording systems at well drilling and workover sites are used for in-process control and help to analyze how teams respond to contingencies.

10 well control teams with the total headcount of about 1K people ensure effective emergency response.

To mitigate the emergency risks at the Company's facilities, Rosneft implements geotechnical monitoring project. It covers R&D work to assess climate change and its impact on construction and operational safety, process automation, development of monitoring methodology and training system for Company’s employees.

As a part of the targeted innovation project called "Technology development for geotechnical monitoring system", the Company will organize and develop geotechnical monitoring activities at its sites. These will include fundamental studies of current geocryological processes, forecasting of changes amidst the global climate change, description and development of research related to foundations built on permafrost.

Rosneft’s representatives participate in meetings and conferences organized by state authorities, federal and regional ministries and departments to share views, best practices and adopt joint resolutions on development of the geotechnical monitoring system and analysis of the current condition of permafrost soils, including those located in the RF Arctic zone.

Rosneft is continuously developing its multi-level aviation safety control system, which helps to control the quality and safety of aviation services at different management and organizational levels, both in contracting airlines and in subsidiaries.

The Company is a member of the Aviation Services Customers Committee under the Helicopter Industry Association. As part of its work, Rosneft participates in shaping of a draft Regulation on aviation support, among the companies of the Russian oil and gas industry. The document will unify the requirements to aviation contractors. This will help to systemize the requirements of oil and gas companies to air carriers, which will improve safety and quality of aviation support by upscaling best practices and uniform requirements.

-315xx70.png)